Do not wear gloves, rings, watches, or bracelets while working with a drill press. Do not set speeds, adjust, or measure work until machine is completely stopped. Do not force the drill with extra pressure. Do not hold work by hand when drilling holes; secure the …

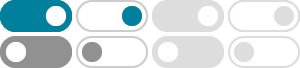

Description of Work: Using a drill press (bench or pedestal). Potential Hazards: Exposed moving parts and electrical hazard with the potential to cause harm through entanglement, exposure to heat, dust, projectiles and sharp objects. Personal Protective Equipment (PPE) Required (Check the box for required PPE) Safety Protective Eye Protection ...

drill press is used and they may change depending on the operations being performed. 10 POTENTIAL HAZARDS The primary hazards of drill presses are contact at the point of operation and rotational hazards. An operator can risk serious hand injury when working too close to the drilling area, wearing gloves, loose clothing, loose hair, or jewelry.

Required PPE: Safety Glasses, Closed Toe Shoes, and Long Pants Turn on Drill Press Rotating Parts, Pinch Points, High Noise, and Flying Debris. Be aware of hand/body placement due to rotating parts/pinch point hazards. Wear safety glasses to prevent eye injury.

Drill Press Machine Checklist for Safety Inspection - Global EHS

Drill Press Machine Safety Inspection Checklist. It is also known as Stand Drill Machine. Drill Press Machine should be physically in good condition without any cuts, cracks, ware and tare in it. All moving parts like belt, spindle pully etc should be covered with guard. Feed handle should be working smoothly and free from defects.

All disconnecting means enclosures are marked with a safety sign in accordance with ANSI Z535.4 to warn qualified persons of potential electric shock and arc flash hazards. A minimum of 36 inches of clearance is provided in front of disconnecting means to ensure safe maintenance.

Safety Information for the University of California, Berkeley DEPARTMENT OF MECHANICAL ENGINEERING OPERATING A DRILL PRESS TASK HAZARDS CONTROLS 1. •Assess work area; is it clear of obstructions and slip/trip/fall hazards? Slip, trip, or fall • Clear work area of any obstructions or slip/trip/fall hazards 2.

Drill Press Safety • Ensure all safety shields and guards are in place. • Know the location of start and stop switches or buttons. • Use only properly sharpened drill bits, sockets and chucks in good condition. Remove dull drill bits, battered tangs, or sockets from service. • Use the proper cutting fluid for the materials being drilled.

Check that the drill press is in working condition. Get into the habit of doing. a "pre-flight" checking procedure. Keep in mind that you do not know who or for what the drill press was used prior to your arrival. The following should be checked before use. …

OPERATIONAL SAFETY CHECKS 1. Never leave the drill press while it is running. 2. Before making adjustments or before cleaning swarf accumulations switch off and bring the machine to a complete standstill. 3. Feed downwards at a sufficient rate to keep the drill cutting. 4. Feed with care as the drill breaks through the underside of the work.